Capabilities

-

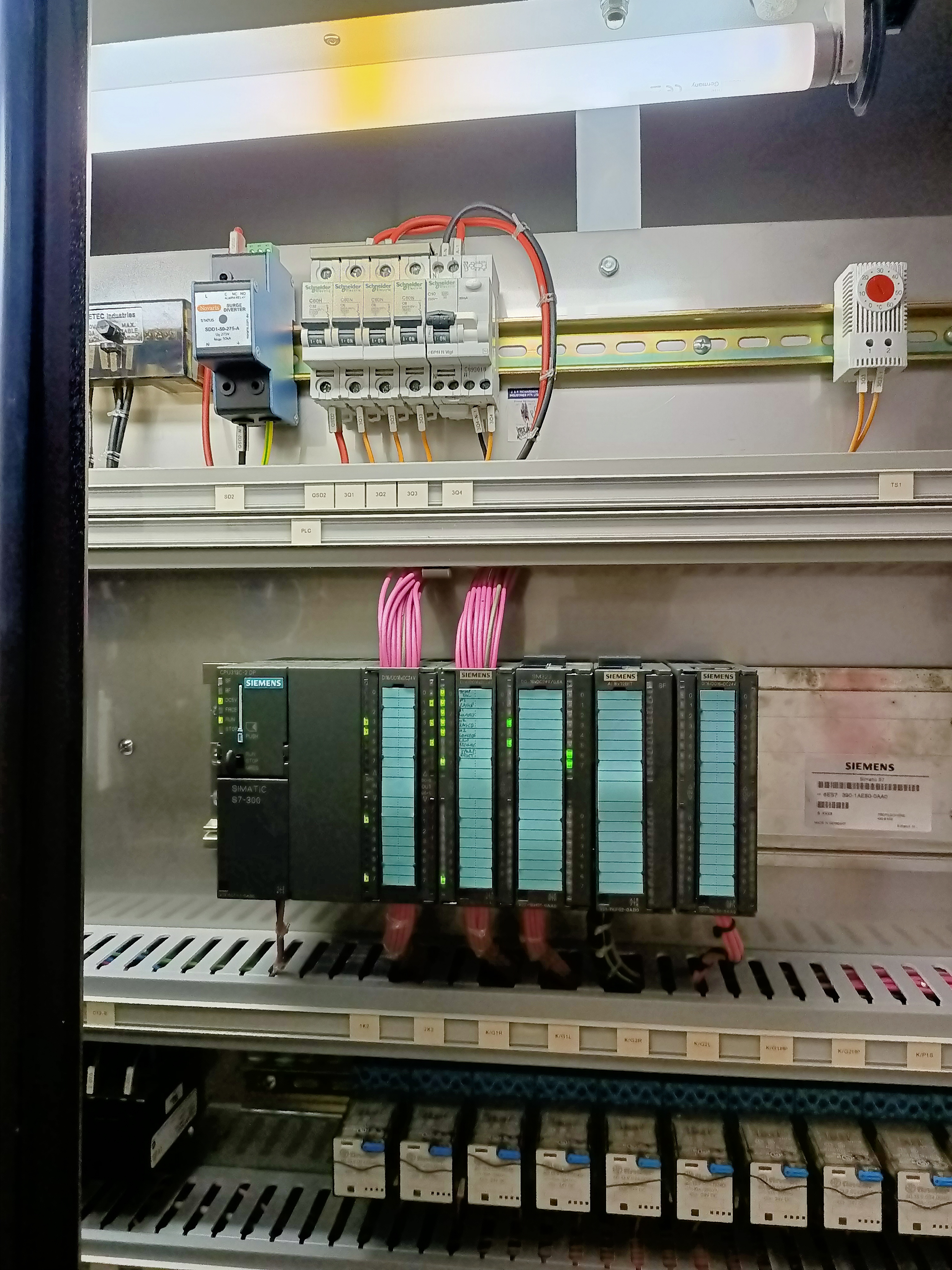

Programmable Logic Controllers (PLC); and associated modules - Including Remote I/O modules

-

Remote Telemetry Units (RTU)

-

Supervisory Control and Data Acquisition (SCADA)

-

Human Machine Interface (HMI)

-

Process Control Network (PCN) and its Physical Infrastructure aspects

-

Switches, Communication modules, Routers, Firewalls and Protocol convertors

-

Control System Cabling and Wiring | Copper & Fibre Optic Networks

-

Wireless / Radio communication modules

-

-

Industrial Communication Protocols: EtherNet I/P, PROFIBUS, PROFINET, MODBUS, DeviceNet, DNP3, and OPC connectivity (OPC DA, OPC HDA, OPC UA, and OPC A&E)

-

Control Panels / Physical enclosures

-

Alarm & Event Management; and Sequence of Event (SOE) Recording | Alarm & Event Historian

-

PLC Programs / Control Logic; Safety Interlocks

-

HMI / SCADA Software objects

-

PLC Dataloggers

-

Real-Time Plant Data Historians (Time-series data)

-

Relevant standards and best practices surrounding industrial automation & control systems (ISA / IEC)

Service Offerings

Leveraging the above technological capabilities, we are able to support our Customers, with the following service offerings, so as to suit their specific business situation & need.

-

Delivering a brand-new Control System Infrastructure,

-

for a Greenfield facility (for whole of the asset or for one / more plant sections)

-

for a Brownfield environment, if the existing processes are currently manual or semi-automatic

-

-

Uplifting the existing Control System Infrastructure into a more modernised & and Industry Standard environment

-

Renewals / Upgrades of the Control System hardware and software to address (a) End-of-Life (EOL) situations (b) unavailability of support & spares scenarios

-

Adding new Control System capabilities / Modifications in the existing Control System

-

On-going Continuous Improvements & Fine-Tuning as generally required in Control Systems (including changes in PLC logic, SCADA software objects etc)

Note : In addition to the above, we will be also able to do pure resource augmentation (Specialist skills supply, Project Management support etc), in the event, customer’s team prefers it (for assisting control system projects directly managed and delivered by their own in-house team).

Typical activities we normally do (as part of our service offerings)

Having noted the above two sections, the following constitutes the set of work-activities, our team normally carries out in a ‘typical’ Control System project (medium to large scale), if it is managed & delivered by us (However this list could vary depending on the scope of project, business need and model of engagement with our Customers).

-

Requirements Gathering, Analysis, Validation & Getting Customer’s Sign-Off

-

This also includes gathering surrounding information / facts & figures around the project environment

-

-

Current State Evaluation (As-Is) | Future State Definition (To-Be) | Gap Analysis between the two states

-

Site Audits | Assessments to understand project complexities; Risk Identification & Establish Mitigation Measures

-

Defining the Scope of delivery of the Project, through a Scope-of-Works (SOW) artefact

-

Preparing the Delivery Project Schedule (Tasks, Timelines, Resources and Inter-dependencies)

-

Defining Implementation Strategy: - (a) Implementation Planning (b) Defining Work Break-Down Structure -WBS (c) Develop Project Management Plan (PMP)

-

Solution Architecting and Detailed Design – Few of design deliverables as below (but not limited to)

-

Functional Design Specifications

-

Network Architecture Diagram (depicting PLC, Remote IO, SCADA, HMI, Process Control Network etc)

-

PLC Panel layout drawings

-

General Arrangement (GA) diagrams

-

I/O list

-

Master Alarm Register

-

Cause & Effect Diagram

-

Loop Diagrams

-

Cable Schedule

-

Fibre Optic layout

-

Hardware Bill-of-Materials (For PLC CPU, Remote IO, HMI, Network components, Commissioning Materials etc)

-

Software Bill-of-Materials (Licences)

-

PLC / SCADA programming approach

-

-

Procurement activities (of Hardware, Software and other supplies from respective vendors)

-

Solution Build / Development / Configurations: This includes but not limited to

-

PLC programming, including Safety Interlocks development

-

SCADA displays development

-

HMI displays development

-

Panel builds

-

Finalising hardware settings / configurations

-

-

Factory Acceptance Testing (FAT)

-

Site Installation / Implementation / Commissioning activities (Including Systems Integration and related Deployments)

-

This normally involves site-based works of Electrician on wiring / cabling and other related electrical works; Fibre Optic Contractor scope and related works where necessary

-

-

Site Acceptance Testing (SAT)

-

Identify SAT Issues and get them resolved & reach Solution Acceptance stage

-

End User Training, and Transition to Operations & On-going Support Team (including delivering AS-CONSTRUCTED / AS-BUILT Documentation)

-

Project Close out

Note : Our supply also includes Project Management Efforts from Start to Finish for the above.

Wherever necessary, we will be able to support the customer’s in-house teams, on the following preliminary / early-stage works, for the Project to get off-the ground.

-

Pre- Feasibility / Feasibility Studies

-

Developing Business Case & Project Justifications

-

Securing Project Funding & necessary Approvals, and facilitate progress towards Project Execution phase